Taylor Valve Technology

King's Energy Services Ltd. is the Canadian Distributor for Taylor Valve Technology products. Located in the heart of Alberta's oil patch, King's Energy has been handling, repairing and distributing Taylor Valve products since 1989. We carry a large inventory of valves and valve-related stock to accommodate orders quickly and efficiently.

Certified by the National Board of Boiler and Pressure Vessel Inspectors (NB), the American Petroleum Institute (API), and the American Society of Mechanical Engineers (ASME), Taylor Valve Technology has been engineering and manufacturing world-class products since 1958. Their creativity and innovation have propelled them to the forefront of today’s global oil, gas and industrial markets.

Taylor Valve Technology's commitment to research and development combined with the product support offered by King’s Energy enables quick, efficient and economical service. Further, our engineers frequently design customized solutions and products to help solve engineering dilemmas for our customers. Contact us with your questions.

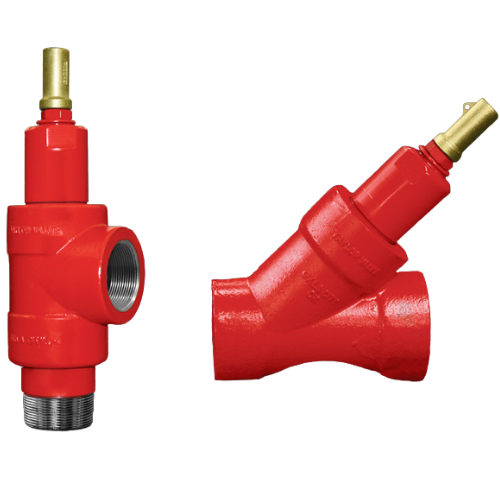

7700 Series Back Pressure Regulator

The 7700 Back Pressure Regulator (BPR) Series is an excellent and economical device for relief and control of pressure in liquid and gas service. Valve control is accomplished by upstream pressure acting on a lapped piston, which is acted on by a spring. The valve will open at a determined set pressure, which is field adjustable.

Applications

Pump Bypass, Pump Relief, Well Hookups and Closed Loop Systems, Balanced Valve Applications, By- Pass to Casing, Pump Backpressure - Allows the pump to operate more efficiently, Pipeline Thermal Relief

Request More Information

8400 Series Vapor Valve

The 8400 Series Vapor Valve provides pressure relief in applications where hazardous vapors are to be piped away. The Vapor Valve is a non-ASME code valve, and specifically addresses low-pressure applications (below 15 PSIG). The valve uses a spring which directly opposes system pressure. A fully-guided, stainless steel disc senses the system pressure. If the system pressure ever reaches the valve’s determined set pressure, the disc will release from its seated position, venting system pressure.

Applications

Glycol Reboiler Safety Relief, BTEX Safety Relief, Vessel Safety Relief below 15 PSI and Tank Blanketing.

EPC Environmental Protection Cap

DESCRIPTION

The EPC ensures valve and system protection from environmental elements, enhancing service life and limiting repair costs. Our unique lanyard design and NOW our new threaded option add a leak detection capability that sets us apart from other competitive products.

LANYARD SPECS

Connection Size: 1/2″ – 4″

Connection Type: Lanyard Strap

Body Material: Vinyl and highly engineered plastic compound

Max. Working Pressure: 3,000 psi

The design also incorporates a whistle device that signals when a low-pressure leak is occurring.

NOTE: Taylor Valve reserves the right to change product designs and specifications without notice.

THREADED SPECS

Connection Size: 1″- 2″

Connection Type: Threaded

Body Material: Nylon 6-6

Max. Working Pressure: 3,000 psi

NOTE: Taylor Valve reserves the right to change product designs and specifications without notice.

APPLICATIONS

Valve and System Protection, Leak Detection.

Applications

Valve and System Protection, Leak Detection.

Request More Information

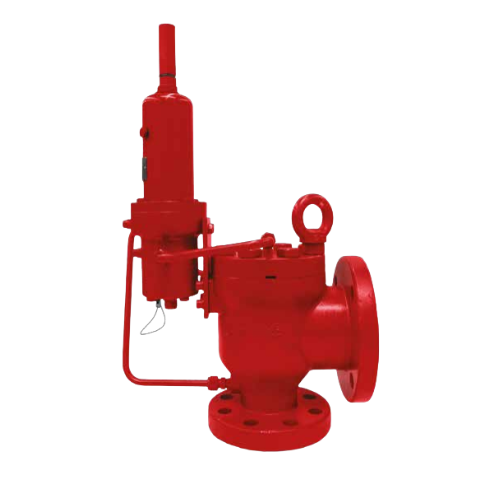

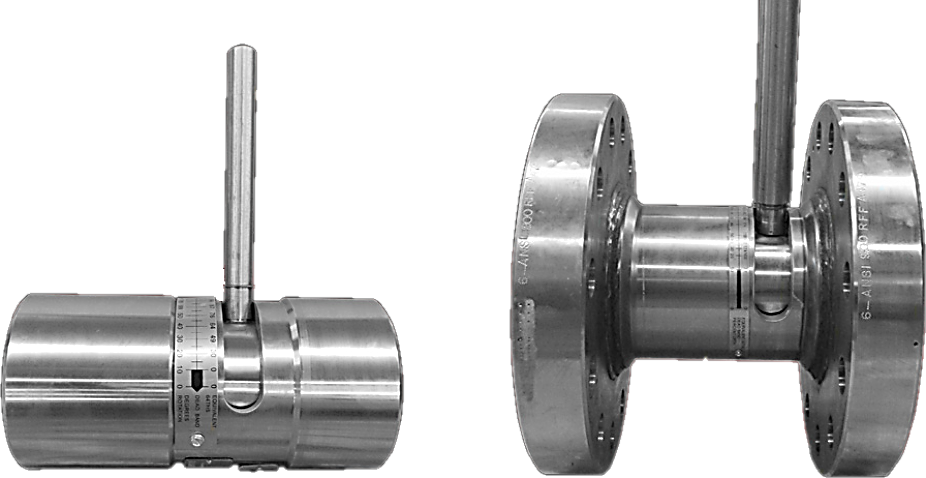

8200/8300 Series Safety Relief Valve

Our 8200/8300 Series safety relief valves are engineered and manufactured to the highest standards and feature a high endurance soft seat which guarantees a bubble-tight seal for hundreds of “pops”. Our unique patented radius disc design guarantees dependable, repeatable relief even under the most difficult of conditions.

Available in flanged or threaded configurations.

Taylor Valve Technologies 8200 Series are no longer being produced Kings Energy Services can support 8200 series valves that are in service. If you require a replacement for your 8200 Series please to Taylor Valve Technologies new 8250 Series.

Download the brochure for more information and complete valve specifications.

Applications

Air, gas, or liquid relief applications, compressors, separators, heater treaters, free water knockouts, scrubbers, dehydrators, thermal relief, gas production units chemical plants, refineries, gas, plants and other industrial applications.

9300 Modulator Pilot Valve

The Series 9300 Modulator Pilot Valve / Modulating Safety Valve with the non-flowing pilot provides highly reliable system overpressure protection.

Features & Benefits

- Easily Adjusted

The adjustable set pressure is accurate and dependable. Adjustable blowdown is external, which reduces time and cost consuming expenditures of valve removal. System downtime is also greatly reduced. - Maintenance Cost Is Cut

With a replaceable soft seat, expensive parts and time-consuming lapping of metal seats are no longer necessary. - ASME Section VIII Code Stamp

Used for air, gas, and vapor service, the capacity is assured by an independent third party, the ASME National Board Laboratory in Columbus, Ohio. - Increased Output of System

The valve can be set within 5% of system operating pressure allowing the process to be maintained at close tolerance without valve leakage. This results in greater process system output. - Dirty Service

The pilot is a non-flowing design minimizing the entry of dirt and the accumulation of hydrates. Most of the contaminates will be removed in the coalescing filter upstream of the pilot. The internal cartridge type filter is standard on all Taylor Pilots and finishes the gas before it enters the pilot cavity. Inline tubing external filter is also available. - Pilot is Mounted Vertically

Consistent set pressure and blowdown are assured compared to horizontally mounted pilots that are erratic.- Orifice Nozzles. The orifice size may be changed by replacing a single component. There are multiple orifice sizes for each nominal body size.

- Built-in Field Test Port. Provides the ability to accurately verify the set pressure with the valve in place and in service.

- Durable, Rugged Mounting of Pilot. Extra rigid mounting against the body protects the pilot from system vibration.

Applications

This valve can be used for air, gas, vapor, and most mixed-phase services.

Request More Information

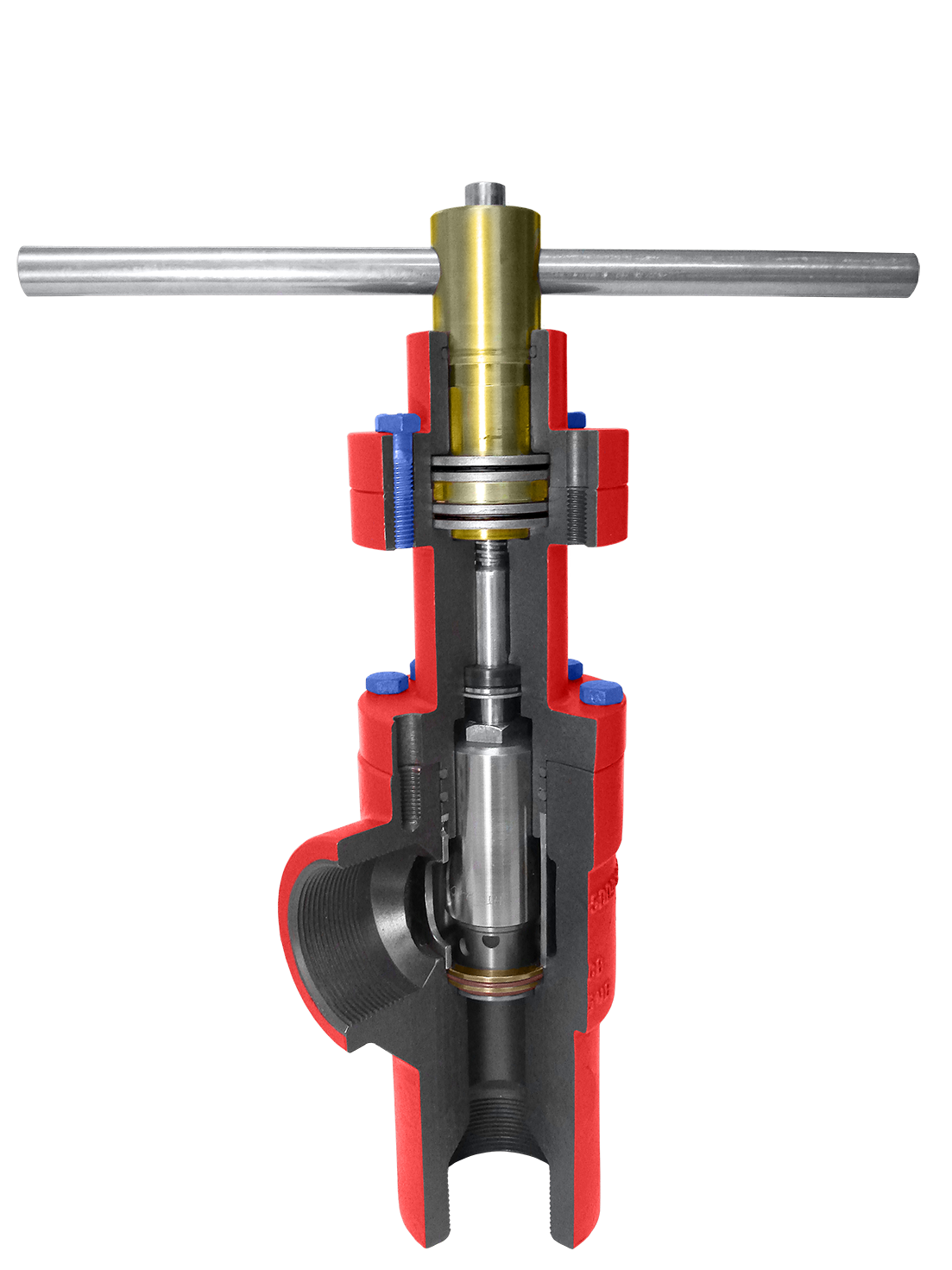

R1 Series Choke Valve

The R1 Series Control Valve features several unique design characteristics that minimize wear and maximize service life.

The nozzle and external sleeve trim is designed to contain turbulence and wear by managing the flow into the nozzle and centralizing it into bore causing the flow streams to impinge on each other. The valve body and outlet are protected from wear because the energy conversion as a result of the pressure drop is concentrated in the trim cavity before flow enters the outlet. This eliminates the typical wear problems in the valve outlet.

The sleeve design greatly reduces the breakaway and closing thrust requirements to lift the sleeve on and off the seat as well as during stem travel making the control stable and precise yielding better accuracy and repeatability.

SPECIFICATIONS:

Connection Size: 1″

Connection Type: Threaded, Flanged

Body Style: Angled

Body Material: Low Alloy (4130 LACS)

Process Fluid: Vapor

Cv: 12 (Standard), 6, 3

Bean Size: 47/64ths

Stroke Length: 1”

Stem Diameter: 0.625”

MAWP: 5,000 PSIG

Additional Benefits:

- Accurate Control – Multi-Orifice Nozzle design provides precise control over a wide range of flows.

- Bolted Bonnet – A bolted bonnet prevents corrosion, cross-threading and galling of large threaded connections. The design allows for simple assembly and disassembly.

- Extended Mean Time Between Service – Robust design, application of hardened materials, and efficient flow geometry results in maximum production potential and minimum service requirements.

- Easy Maintenance – All Control Choke Valves are designed with special actuator mounting systems so the choke can be maintained without disassembly of the actuator and components or instrument connections.

- High Turndown Ratio – Clean flow geometry, high capacity, and accurate control mean the valve is suitable for both start-up and end-of field-life-process scenarios. In short, our control choke valves offer a one-valve solution for the full process life.

Optional Features:

Control Valves can have trims and actuators custom-designed for specific requirements. Such as special noise reduction trims, reduced port and maximum orifice trims for very high pressure or minimum pressure loss for a declining field.

SPECIFICATIONS

Please download the Product Brochure PDF for more information.

APPLICATIONS:

- Well Site Automated and Manual Application

- Water Injection Control Valve

- CO2 Injection Control Valve

- High-Pressure Drop Applications

- Gas Lift Injection Control

CI / CA Choke Valves

The C series is a variable orifice valve economically designed to provide accurate and dependable flow control and an increased valve life under all types of conditions and applications.

SPECIFICATIONS:

Connection Size: 1″ FNPT

Connection Type: Threaded

Body Style: CA: Angled, CI: Inline

Body Material: 316 Stainless Steel

Process Fluid: Liquid, Gas

Max. Working Pressure: 2,000 psi

Additional Features:

- Ceramic trim is standard with optional Tungsten Carbide

- 1/4 turn Full Range

- ANSI Class IV Shutoff

- Compact, light-weight design

APPLICATIONS:

High-pressure drop applications in gas, liquid, and vapor. Quick open/close with abrasive fluids at high-pressure drops.

FEATURES:

- Compact, Light-Weight Design

- 316ss Construction

- Ceramic Trim or Tungsten Carbide Trim Available

- 1/4 turn operation

- 3705psi MWP

- 1"FNPT end Connections

- ANSI CLASS V Shutoff

Please download the Product Brochure PDF for more information.

MDI / MDA Choke Valves

MDI / MDA Series Chokes are made with wear-resistant material to extend service life, with redundant O-Rings on the Bonnet Seals and Stem Seals that help prevent leakage. Fully Guided Stems reduce imbalance and vibration. Control Discs provide ANSI Class III/IV Shut off.

SPECIFICATIONS:

Connection Size: 1″, 2″, 3″

Connection Type: Threaded, Flanged, Butt Weld

Body Style: Angled

Body Material: 1018/1020 CS, 316 SS

Process Fluid: Gas, Liquid, Steam

MDI

Body Rating: 1″ & 2″ – 5,000 PSI, 3″ – 3,000 PSI

CV Range: 1″ & 2″ – 0.7 – 23.86, 3″ – 11.2 – 84.65

MDIS

Body Rating: 1″ & 2″ – 5,000 PSI, 3″ – 3,000 PSI

MAWP: 1333 PSI for Steam

CV Range: 1″ & 2″ – 0.7 – 23.86, 3″ – 11.2 – 84.65

Additional Benefits:

Accurate Control – 90 degree rotation from Full Off to Full On.

Bolted Bonnet – Safety Bonnet is bolted into the body, it avoids the well-known risks of corrosion, cross threading, galling of threaded type connection in production environments.

Extended Mean Time Between Service – Robust design and liberal application of hardened materials, efficient flow-geometry means the valves offer maximum production potential and minimum service requirements.

Easy Maintenance – Repair parts can be installed in the field without removing the valve from the line.

Optional Features:

Choke Valves can have trims and actuators custom designed for specific requirements. Such as special noise reduction trims, reduced port and maximum orifice trims, and for very high pressure or minimum pressure loss for a declining field.

APPLICATIONS:

High pressure drop applications in gas, liquid, and vapor. Quick open/close with abrasive fluids at high pressure drops.

- Well Site Automation

- Blow Down and Dump Valve

- Water Injection Control Valve

- Remote Control for directional drilling

- CO2 Injection Control Valve

- Steam Injection

- Pump Bypass

- Steam Tracer Control

- Pump Startup

- Manual and Automated Application

- Gas Lift Injection Control

- High Temperature Protection

Please download the Product Brochure PDF for more information.

Request More Information

MC Inline Choke

The MC Series pressure and flow control valves feature a superior design for unequaled throttling and accuracy. Unique sealing and fluid flow dynamics permit compliance with current environmental (FTE) requirements.

SPECIFICATIONS:

Connection Size: 1″-2″ Threaded, 3″ Flanged

Connection Type: Threaded, Flanged, Butt Weld, and Victaulic End

Body Style: Inline

Body Material: 316 SS

Process Fluid: Gas, Liquid, Vapor

Max. Working Pressure: 3,600 psi

CV Range: 0.70 – 16.57

Additional Benefits:

- Accurate Control – 90-degree rotation from Full Off to Full On

- Bolted Body – Body is constructed with two bolted segments, avoiding the risk of corrosion, cross-threading, galling of threaded type valve assemblies.

- Extended Mean Time Between Service – Robust design and liberal application of hardened materials, efficient flow-geometry means the valves offer maximum production potential and minimum service requirements.

- Easy Maintenance – Choke valves are designed to provide simple straightforward disassembly with no special tooling or fixtures.

Optional Features: Choke valves can have trims and actuators custom-designed for specific requirements, such as special trims for noise reduction and sand control, several trims are available to accommodate high pressure flows or minimum pressure loss applications.

APPLICATIONS:

High-pressure drop applications in gas, liquid, and vapor. Quick open/close with abrasive fluids at high-pressure drops.

- Well Site Automation

- Water Injection Control Valve

- CO2 Injection Control Valve

- Pump Bypass

- Pump Startup

- Gas Lift Injection Control

- Blow Down and Dump Valve

- Steam Injection

- Throttling Valve

- High DP Valve

- Motor Operated Valve

This choke has several advantages including:

- Superior trim design for unequaled throttling control and accuracy in the process environment

- The unique flow path through the trim for superior resistance to cavitation and increased stability of trim.

- Durable, high-quality construction for longer life and drastically reduced maintenance.

- orifice position is displayed clearly.

- Control surfaces are separated from sealing surfaces.

- Unique sealing and fluid flow dynamics permit compliance with current environmental (FTE) requirements.

- Seal tightness ratings are superior to any competitive product model.

- Easy to set - 1/4 turn for the full range.

- Economically priced

Please download the Product Brochure PDF for more information.

Request More Information

RB Series Chokes

The RB Series unique valve trim design provides accurate control by the use of precision orifices in the flow nozzle. This design minimizes wear and maximizes service life.

SPECIFICATIONS:

Connection Size: 2″, 3″, 4″, 6″

Connection Type: Flanged

Body Style: Angled

Body Material: LACS 4130

RB2 Control Choke

Cv: 6, 12, 35 (Standard)

Bean Size: 78 / 64th’s (Standard)

Stroke Length: 1.25”

Stem Diameter: 0.625”

MAWP: 10,000 PSIG

RB3 Control Choke

Cv: 35, 64 (Standard)

Bean Size: 105 / 64th’s

Stroke Length: 1.75”

Stem Diameter: 0.625”

MAWP: 6,000 PSIG

RB4 Control Choke

Cv: 164

Bean Size: 169 / 64th’s

Stroke Length: 2.45”

Stem Diameter: 0.75”

MAWP: 6,000 PSIG

RB6 Control Choke

Cv: 420

Bean Size: 270 / 64th’s

Stroke Length: 4.25”

Stem Diameter: 1.0”

MAWP: 6,000 PSIG

FEATURES & BENEFITS:

The RB Series Control Valve features several unique design characteristics that minimize wear and maximize service life. The nozzle and external sleeve trim is designed to contain turbulence and wear by managing the flow into the nozzle and centralizing it into bore causing the flow streams to impinge on each other. The valve body and outlet are protected from wear because the energy conversion as a result of the pressure drop is concentrated in the trim cavity before flow enters the outlet. This eliminates the typical wear problems in the valve outlet. The Upstream and Downstream balanced sleeve design greatly reduces the breakway and closing thrust requirements to lift the sleeve on and off seat as well as during stem travel making the control stable and precise yielding better accuracy and repeatability.

Additional Benefits:

Accurate Control – Multi-Orifice Nozzle design provides precise control over a wide range of flows.

Bolted Bonnet – A bolted bonnet prevents corrosion, cross-threading and galling of large threaded connections. The design allows for simple assembly and dissasembly.

Extended Mean Time Between Service – Robust design, application of hardened materials, and efficient flow geometry results in maximum production potential and minimum service requirements.

Easy Maintenance – All Control Choke Valves are designed with special actuator mounting systems so the choke can be maintained without disassembly of the actuator and components or instrument connections.

High Turndown Ratio – Clean flow geometry, high capacity and accurate control means the valve is suitable for both start-up and end-of field-life-process scenarios. In short, our control choke valves offer a one-valve solution for the full process life.

Optional Features:

Control Valves can have trims and actuators custom designed for specific requirements. Such as special noise reduction trims, reduced port and maximum orifice trims for very high pressure or minimum pressure loss for a declining field.

SPECIFICATIONS

Please download the Product Brochure PDF for more information.

APPLICATIONS:

- Well Site Automated and Manual Application

- Water Injection Control Valve

- CO2 Injection Control Valve

- High Pressure Drop Applications

- Gas Lift Injection Control

Request More Information

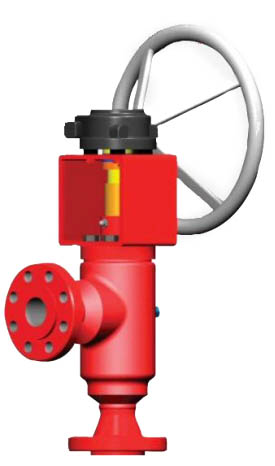

MCX Choke Valve

The MCX Series pressure and flow control valves feature a superior design for unequaled throttling and accuracy. Unique sealing and fluid flow dynamics permit compliance with current environmental (FTE) requirements.

SPECIFICATIONS:

Connection Size: 3″, 4″, 6″

Connection Type: Threaded, Flanged, Butt Weld

Body Style: Inline

Body Material: 1018/1020 CS, 316 SS

Process Fluid: Liquid, Gas, Vapor

Max. Working Pressure: 3,000 PSIG

CV Range: 11.2 – 279.83

Additional Benefits:

- Accurate Control – Superior design is unequaled for throttling control and accuracy. Unique sealing and fluid flow dynamics permit compliance with current environmental requirements.

- Extended Mean Time Between Service – Robust design and liberal application of hardened materials, efficient flow-geometry means the valves offer maximum production potential and minimum service requirements.

- Easy Maintenance – Choke valves are designed to provide simple straightforward disassembly with no special tooling or fixtures.

Optional Features: Choke valves can have trims and actuators custom-designed for specific requirements, such as special trims for noise reduction and sand control, several trims are available to accommodate high pressure flows or minimum pressure loss applications.

APPLICATIONS:

High-pressure drop applications in gas, liquid, and vapor. Quick open/close with abrasive fluids at high-pressure drops.

- Water Injection Control Valve

- Gas Lift Injection Control

- Throttling Valve

- High DP Valve

- Motor Operated Valve

- Enhanced Oil Recovery

Please download the Product Brochure PDF for more information.

Request More Information

8250 Relief Valve

DESCRIPTION

8250 THREADED & FLANGED VALVES

The Taylor 8250 Safety Relief Valve is manufactured in accordance with the requirements of ASME Boiler and Pressure Vessel Code, Section VIII, Division 1 for Air/Gas and Liquid service making it an excellent choice for Air, Gas or Liquid relief applications

The 8250 redesign is just the beginning of new things to come from Taylor Valve, the ORIGINAL SELF ALIGNING TECHNOLOGY company. Self-Aligning seat technology allows for repeatable uses without resetting or repair.

FEATURES

- Designed with self-aligning seat technology

- C orifice with pressure to 10,000 psi

- L orifice in 3 x 4 and 4 x 6 flanged connections

- M orifice in a 4 x 6 flanged connection

- Increased capacity in all orifices

- Top entry style valve H orifice and larger

- API connections available in most flanged connections

- All orifices are ASME certified by the National Board of Boiler and Pressure Vessels in accordance with Sec VIII Div I. for air/gas and liquid service.

SPECIFICATIONS

Please download the 8250 Product Brochure PDF for more information.

APPLICATIONS

- Compressors

- Separators

- Heater Treaters

- Free Water Knockouts

- Scrubbers

- Dehydrators

- Thermal Relief

- Gas Production Units,

- Transmission and Gathering Lines

- Chemical Plants

- Refineries

- Meter Runs

- Gas Plants

- Other Industrial Applications

Request More Information

19BV Series Pressure Relief Valve

DESCRIPTION

19BV Series Pressure Relief Valve

The Taylor 19BV Series Pressure Relief Valve is manufactured in accordance with the requirements of ASME certified by the National Board of Boiler and Pressure Vessels in

accordance to Sec VIII Div I making it an excellent choice for Air, Gas or Liquid relief applications

FEATURES

- Soft seat for reliable, leak free performance to 90% of set pressure

- Easy repair and maintenance

- Balanced disc/cage assembly designed with a single o-ring balancing seal to operate in high back pressure conditions.

- Optimized design allows the valve to operate without chatter or intricate seals.

- ASME certified by the National Board of Boiler and Pressure Vessels in accordance to Sec VIII Div I for air/gas and liquid service.

- NPT threaded and flanged connections

SPECIFICATIONS

Please download the 1900BV Product Brochure PDF for more information.

APPLICATIONS

The Taylor 19BV Pressure Relief Valve has numerous application uses. Since the Series 19BV is certified for both gas and liquid on both orifices, it can be installed

where relief applications that have variable back pressure are present. Thermal valves, pump recycle, separators (liquid side), water knockouts, etc. are just a few examples of

application uses.

Box 187

Box 187

1018 Prescott Dr Unit #2

1018 Prescott Dr Unit #2 NEW

NEW