Taylor Valve Technology is a pioneer in the design, development, and manufacturing of valves and precision instrumentation to meet your pressure, flow, and measurement needs.

By utilizing the latest developments in materials and design, Taylor Valve Technology's choke and back pressure valves are able to offer superior control performance. This line of valves is engineered to meet the demanding specifications of API and ASME Code standards, ensuring successful use in various process applications and guaranteed to meet the most stringent quality standards.

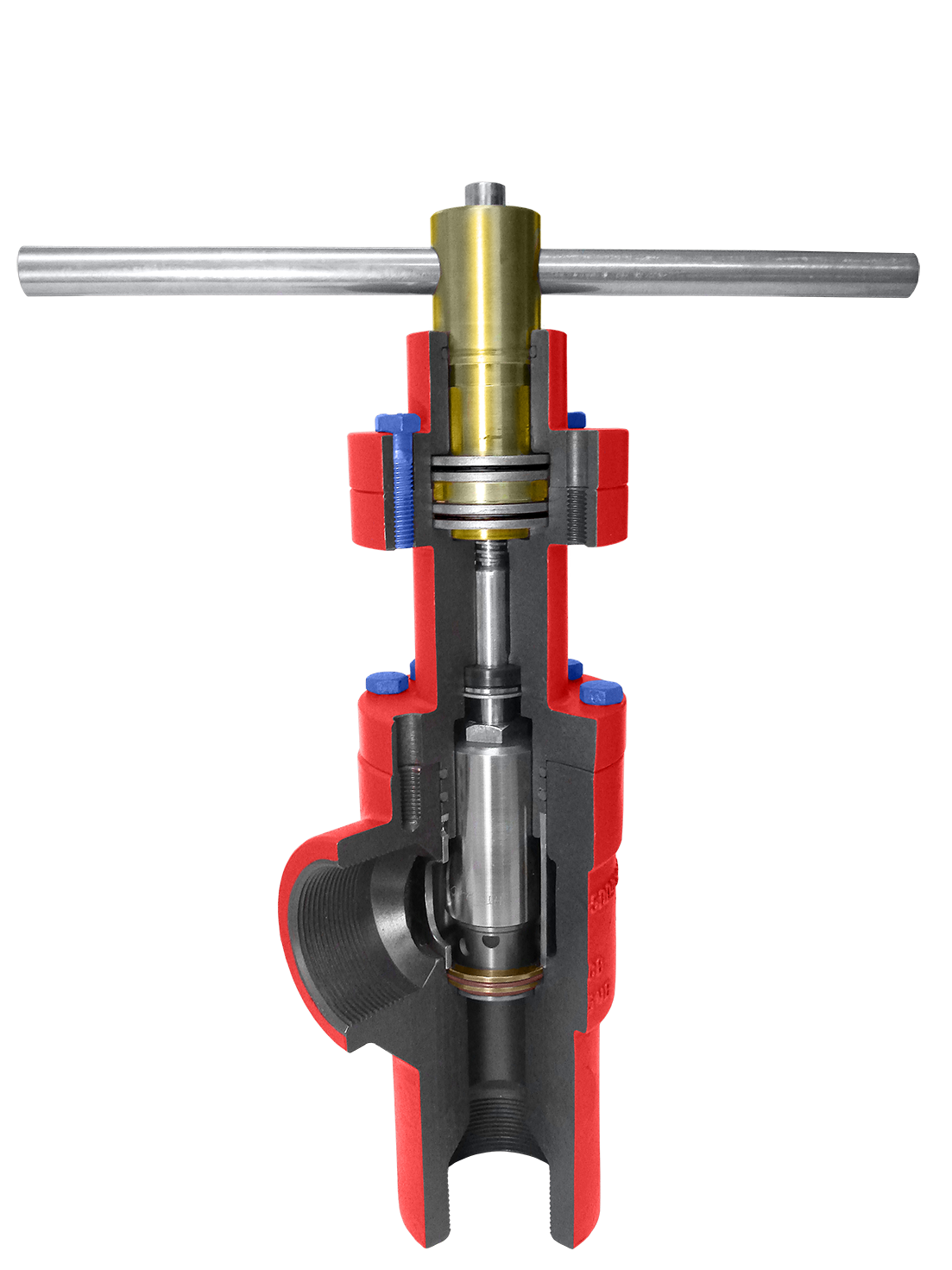

R1 Series Choke Valve

The R1 Series Control Valve features several unique design characteristics that minimize wear and maximize service life.

The nozzle and external sleeve trim is designed to contain turbulence and wear by managing the flow into the nozzle and centralizing it into bore causing the flow streams to impinge on each other. The valve body and outlet are protected from wear because the energy conversion as a result of the pressure drop is concentrated in the trim cavity before flow enters the outlet. This eliminates the typical wear problems in the valve outlet.

The sleeve design greatly reduces the breakaway and closing thrust requirements to lift the sleeve on and off the seat as well as during stem travel making the control stable and precise yielding better accuracy and repeatability.

SPECIFICATIONS:

Connection Size: 1″

Connection Type: Threaded, Flanged

Body Style: Angled

Body Material: Low Alloy (4130 LACS)

Process Fluid: Vapor

Cv: 12 (Standard), 6, 3

Bean Size: 47/64ths

Stroke Length: 1”

Stem Diameter: 0.625”

MAWP: 5,000 PSIG

Additional Benefits:

- Accurate Control – Multi-Orifice Nozzle design provides precise control over a wide range of flows.

- Bolted Bonnet – A bolted bonnet prevents corrosion, cross-threading and galling of large threaded connections. The design allows for simple assembly and disassembly.

- Extended Mean Time Between Service – Robust design, application of hardened materials, and efficient flow geometry results in maximum production potential and minimum service requirements.

- Easy Maintenance – All Control Choke Valves are designed with special actuator mounting systems so the choke can be maintained without disassembly of the actuator and components or instrument connections.

- High Turndown Ratio – Clean flow geometry, high capacity, and accurate control mean the valve is suitable for both start-up and end-of field-life-process scenarios. In short, our control choke valves offer a one-valve solution for the full process life.

Optional Features:

Control Valves can have trims and actuators custom-designed for specific requirements. Such as special noise reduction trims, reduced port and maximum orifice trims for very high pressure or minimum pressure loss for a declining field.

SPECIFICATIONS

Please download the Product Brochure PDF for more information.

APPLICATIONS:

- Well Site Automated and Manual Application

- Water Injection Control Valve

- CO2 Injection Control Valve

- High-Pressure Drop Applications

- Gas Lift Injection Control

Get More Information

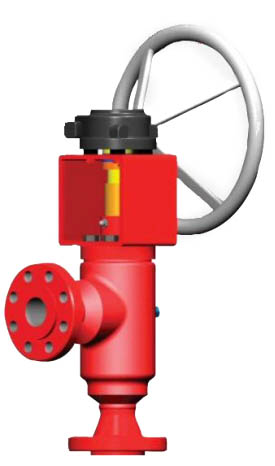

RB Series Chokes

The RB Series unique valve trim design provides accurate control by the use of precision orifices in the flow nozzle. This design minimizes wear and maximizes service life.

SPECIFICATIONS:

Connection Size: 2″, 3″, 4″, 6″

Connection Type: Flanged

Body Style: Angled

Body Material: LACS 4130

RB2 Control Choke

Cv: 6, 12, 35 (Standard)

Bean Size: 78 / 64th’s (Standard)

Stroke Length: 1.25”

Stem Diameter: 0.625”

MAWP: 10,000 PSIG

RB3 Control Choke

Cv: 35, 64 (Standard)

Bean Size: 105 / 64th’s

Stroke Length: 1.75”

Stem Diameter: 0.625”

MAWP: 6,000 PSIG

RB4 Control Choke

Cv: 164

Bean Size: 169 / 64th’s

Stroke Length: 2.45”

Stem Diameter: 0.75”

MAWP: 6,000 PSIG

RB6 Control Choke

Cv: 420

Bean Size: 270 / 64th’s

Stroke Length: 4.25”

Stem Diameter: 1.0”

MAWP: 6,000 PSIG

FEATURES & BENEFITS:

The RB Series Control Valve features several unique design characteristics that minimize wear and maximize service life. The nozzle and external sleeve trim is designed to contain turbulence and wear by managing the flow into the nozzle and centralizing it into bore causing the flow streams to impinge on each other. The valve body and outlet are protected from wear because the energy conversion as a result of the pressure drop is concentrated in the trim cavity before flow enters the outlet. This eliminates the typical wear problems in the valve outlet. The Upstream and Downstream balanced sleeve design greatly reduces the breakway and closing thrust requirements to lift the sleeve on and off seat as well as during stem travel making the control stable and precise yielding better accuracy and repeatability.

Additional Benefits:

Accurate Control – Multi-Orifice Nozzle design provides precise control over a wide range of flows.

Bolted Bonnet – A bolted bonnet prevents corrosion, cross-threading and galling of large threaded connections. The design allows for simple assembly and dissasembly.

Extended Mean Time Between Service – Robust design, application of hardened materials, and efficient flow geometry results in maximum production potential and minimum service requirements.

Easy Maintenance – All Control Choke Valves are designed with special actuator mounting systems so the choke can be maintained without disassembly of the actuator and components or instrument connections.

High Turndown Ratio – Clean flow geometry, high capacity and accurate control means the valve is suitable for both start-up and end-of field-life-process scenarios. In short, our control choke valves offer a one-valve solution for the full process life.

Optional Features:

Control Valves can have trims and actuators custom designed for specific requirements. Such as special noise reduction trims, reduced port and maximum orifice trims for very high pressure or minimum pressure loss for a declining field.

SPECIFICATIONS

Please download the Product Brochure PDF for more information.

APPLICATIONS:

- Well Site Automated and Manual Application

- Water Injection Control Valve

- CO2 Injection Control Valve

- High Pressure Drop Applications

- Gas Lift Injection Control

Get More Information

CI / CA Choke Valves

The C series is a variable orifice valve economically designed to provide accurate and dependable flow control and an increased valve life under all types of conditions and applications.

SPECIFICATIONS:

Connection Size: 1″ FNPT

Connection Type: Threaded

Body Style: CA: Angled, CI: Inline

Body Material: 316 Stainless Steel

Process Fluid: Liquid, Gas

Max. Working Pressure: 2,000 psi

Additional Features:

- Ceramic trim is standard with optional Tungsten Carbide

- 1/4 turn Full Range

- ANSI Class IV Shutoff

- Compact, light-weight design

APPLICATIONS:

High-pressure drop applications in gas, liquid, and vapor. Quick open/close with abrasive fluids at high-pressure drops.

FEATURES:

- Compact, Light-Weight Design

- 316ss Construction

- Ceramic Trim or Tungsten Carbide Trim Available

- 1/4 turn operation

- 3705psi MWP

- 1"FNPT end Connections

- ANSI CLASS V Shutoff

Please download the Product Brochure PDF for more information.

Get More Information

MDI / MDA Choke Valves

MDI / MDA Series Chokes are made with wear-resistant material to extend service life, with redundant O-Rings on the Bonnet Seals and Stem Seals that help prevent leakage. Fully Guided Stems reduce imbalance and vibration. Control Discs provide ANSI Class III/IV Shut off.

SPECIFICATIONS:

Connection Size: 1″, 2″, 3″

Connection Type: Threaded, Flanged, Butt Weld

Body Style: Angled

Body Material: 1018/1020 CS, 316 SS

Process Fluid: Gas, Liquid, Steam

MDI

Body Rating: 1″ & 2″ – 5,000 PSI, 3″ – 3,000 PSI

CV Range: 1″ & 2″ – 0.7 – 23.86, 3″ – 11.2 – 84.65

MDIS

Body Rating: 1″ & 2″ – 5,000 PSI, 3″ – 3,000 PSI

MAWP: 1333 PSI for Steam

CV Range: 1″ & 2″ – 0.7 – 23.86, 3″ – 11.2 – 84.65

Additional Benefits:

Accurate Control – 90 degree rotation from Full Off to Full On.

Bolted Bonnet – Safety Bonnet is bolted into the body, it avoids the well-known risks of corrosion, cross threading, galling of threaded type connection in production environments.

Extended Mean Time Between Service – Robust design and liberal application of hardened materials, efficient flow-geometry means the valves offer maximum production potential and minimum service requirements.

Easy Maintenance – Repair parts can be installed in the field without removing the valve from the line.

Optional Features:

Choke Valves can have trims and actuators custom designed for specific requirements. Such as special noise reduction trims, reduced port and maximum orifice trims, and for very high pressure or minimum pressure loss for a declining field.

APPLICATIONS:

High pressure drop applications in gas, liquid, and vapor. Quick open/close with abrasive fluids at high pressure drops.

- Well Site Automation

- Blow Down and Dump Valve

- Water Injection Control Valve

- Remote Control for directional drilling

- CO2 Injection Control Valve

- Steam Injection

- Pump Bypass

- Steam Tracer Control

- Pump Startup

- Manual and Automated Application

- Gas Lift Injection Control

- High Temperature Protection

Please download the Product Brochure PDF for more information.

Get More Information

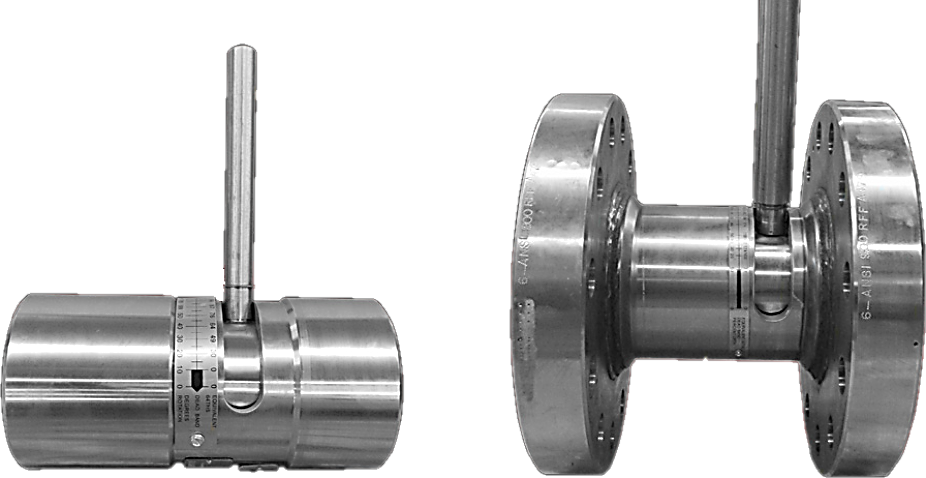

MC Inline Choke

The MC Series pressure and flow control valves feature a superior design for unequaled throttling and accuracy. Unique sealing and fluid flow dynamics permit compliance with current environmental (FTE) requirements.

SPECIFICATIONS:

Connection Size: 1″-2″ Threaded, 3″ Flanged

Connection Type: Threaded, Flanged, Butt Weld, and Victaulic End

Body Style: Inline

Body Material: 316 SS

Process Fluid: Gas, Liquid, Vapor

Max. Working Pressure: 3,600 psi

CV Range: 0.70 – 16.57

Additional Benefits:

- Accurate Control – 90-degree rotation from Full Off to Full On

- Bolted Body – Body is constructed with two bolted segments, avoiding the risk of corrosion, cross-threading, galling of threaded type valve assemblies.

- Extended Mean Time Between Service – Robust design and liberal application of hardened materials, efficient flow-geometry means the valves offer maximum production potential and minimum service requirements.

- Easy Maintenance – Choke valves are designed to provide simple straightforward disassembly with no special tooling or fixtures.

Optional Features: Choke valves can have trims and actuators custom-designed for specific requirements, such as special trims for noise reduction and sand control, several trims are available to accommodate high pressure flows or minimum pressure loss applications.

APPLICATIONS:

High-pressure drop applications in gas, liquid, and vapor. Quick open/close with abrasive fluids at high-pressure drops.

- Well Site Automation

- Water Injection Control Valve

- CO2 Injection Control Valve

- Pump Bypass

- Pump Startup

- Gas Lift Injection Control

- Blow Down and Dump Valve

- Steam Injection

- Throttling Valve

- High DP Valve

- Motor Operated Valve

This choke has several advantages including:

- Superior trim design for unequaled throttling control and accuracy in the process environment

- The unique flow path through the trim for superior resistance to cavitation and increased stability of trim.

- Durable, high-quality construction for longer life and drastically reduced maintenance.

- orifice position is displayed clearly.

- Control surfaces are separated from sealing surfaces.

- Unique sealing and fluid flow dynamics permit compliance with current environmental (FTE) requirements.

- Seal tightness ratings are superior to any competitive product model.

- Easy to set - 1/4 turn for the full range.

- Economically priced

Please download the Product Brochure PDF for more information.

Get More Information

MCX Choke Valve

The MCX Series pressure and flow control valves feature a superior design for unequaled throttling and accuracy. Unique sealing and fluid flow dynamics permit compliance with current environmental (FTE) requirements.

SPECIFICATIONS:

Connection Size: 3″, 4″, 6″

Connection Type: Threaded, Flanged, Butt Weld

Body Style: Inline

Body Material: 1018/1020 CS, 316 SS

Process Fluid: Liquid, Gas, Vapor

Max. Working Pressure: 3,000 PSIG

CV Range: 11.2 – 279.83

Additional Benefits:

- Accurate Control – Superior design is unequaled for throttling control and accuracy. Unique sealing and fluid flow dynamics permit compliance with current environmental requirements.

- Extended Mean Time Between Service – Robust design and liberal application of hardened materials, efficient flow-geometry means the valves offer maximum production potential and minimum service requirements.

- Easy Maintenance – Choke valves are designed to provide simple straightforward disassembly with no special tooling or fixtures.

Optional Features: Choke valves can have trims and actuators custom-designed for specific requirements, such as special trims for noise reduction and sand control, several trims are available to accommodate high pressure flows or minimum pressure loss applications.

APPLICATIONS:

High-pressure drop applications in gas, liquid, and vapor. Quick open/close with abrasive fluids at high-pressure drops.

- Water Injection Control Valve

- Gas Lift Injection Control

- Throttling Valve

- High DP Valve

- Motor Operated Valve

- Enhanced Oil Recovery

Please download the Product Brochure PDF for more information.

Get More Information

"For over 12 years I have had a strong working relationship with Kings Energy on C02 & Water Injection Systems. To date, we have over 250 Taylor Choke valves with Valvcon electric actuators in our field. I am extremely happy with any correspondence, products and service that Kings Energy provides and would confidently recommend them."

Peter Jensen

Whitecap Resources

Box 187

Box 187

1018 Prescott Dr Unit #2

1018 Prescott Dr Unit #2 NEW

NEW