TMCo has been manufacturing safe, dependable, accurate & affordable Sure Shot single & dual chamber orifice fittings since 2003. With safety and accuracy in mind, no other orifice fitting can compare to the high standards of TMCo's Sure Shot.

- YouTube

Single Chamber Fittings

Single Chamber Fittings are the most widely accepted means for flow measurement of gas and other hydrocarbons in the oil, gas & petrochemical industry.

Sure Shot® single chamber fitting provides both cost and time saving opportunities to the operator.

Single Chamber Features:

Single Chamber Fitting Applications:

- Gas Gathering

- Compressor Stations

- Onshore – Offshore Production

- Coal-Seam Gas Measurement

- Gas Distribution

- Gas Transmission

- Process Gas Plant

Fitting Pressure Ratings:

- ANSI Class 150 (285 PSI CWP)

- ANSI Class 300 (740 PSI CWP)

- ANSI Class 600 (1480 PSI CWP)

Standard Materials of Construction:

- Body Material – A-216 WCB/WCC - Consult factory for any other fitting body material

- Flange Ratings – ANSI Class 150 to ANSI Class 600

- Fitting End Connections – F x W

- Raised Face Flange is standard for ANSI Class 150 to ANSI Class 600

Conforms to the following industry standards:

- AGA 3/API 14.3, ISO-5167

- ANSI B31.3, MSS SP-55, ANSI B16.5

- Fittings conform to NACE MR-01-75-2000

Operating Range:

- Sizes 2” thru 6” ANSI Class 150, 300, & 600

- Temperature -20° F to 275° F (-29° C. to 135° C.)

Quality Check:

- Hydrostatic test 1-1/2 times rated CWP.

- Tested for positive plate seal, pressure tap integrity, seal protrusion and eccentricity

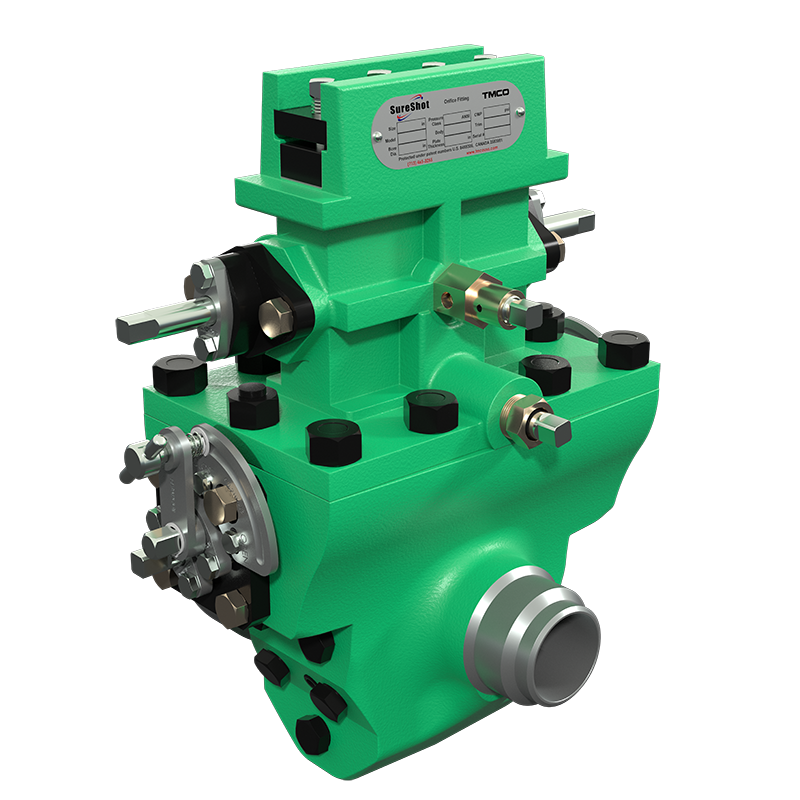

Dual Chamber Orifice Fitting

Sure Shot® Dual Chamber Orifice fittings fully conform to the latest AGA 3/API 14.3 stringent requirements. They require no added uncertainty and provide accurate performance over the orifice plate beta ratio range from 0.1 to 0.75 within 0.5% flow accuracy to theoretical value.

Dual Chamber Features:

- Two-piece body allows fast, safe inexpensive orifice plate change under pressure

- Protected positive orifice plate seal design extends service life

- Meets or exceeds all industry specifications (AGA3/API 14.3)

- 2”-16” ANSI Classes 150-600. For higher ratings consult factory

- Few moving parts, positive sealing with low maintenance

- Unique safety lock helps to prevent accidental opening under pressure while removing the orifice plate, indicates proper carrier location, and provides precise plug operation positioning

Fitting Pressure Ratings:

- ANSI Class 150 (285 PSI CWP)

- ANSI Class 300 (740 PSI CWP)

- ANSI Class 600 (1480 PSI CWP)

Standard Materials of Construction:

- Body Material – A-216 WCB / WCC

- Flange Ratings – ANSI Class 150 to ANSI Class 600 inclusive.

- Fitting End Connections – F x W, F x F ?Note: RTJ Flange facing available upon request. Consult factory for any other fitting body material.

Conforms to the following industry standards:

- AGA 3/API 14.3, ISO-5167

- ANSI B31.3, MSS SP-55, ANSI B16.5

- Fittings available for NACE MR-01-75-2000

- CRN Certified

Operating Range:

- Sizes 2” thru 16” ANSI Class 150, 300, & 600

- Temperature -20° F to 275° F (-29° C. to 135° C.)

- Schedule 40 and schedule 80 standard. Note: Consult factory for larger sizes and other operating conditions.

Quality Check:

- Hydrostatic test 1-1/2 times rated CWP.

- Tested for positive plate seal, pressure tap integrity, seal protrusion and eccentricity

Specifications:

Please download the Product Brochure PDF for more information.

Box 187

Box 187

1018 Prescott Dr Unit #2

1018 Prescott Dr Unit #2 NEW

NEW