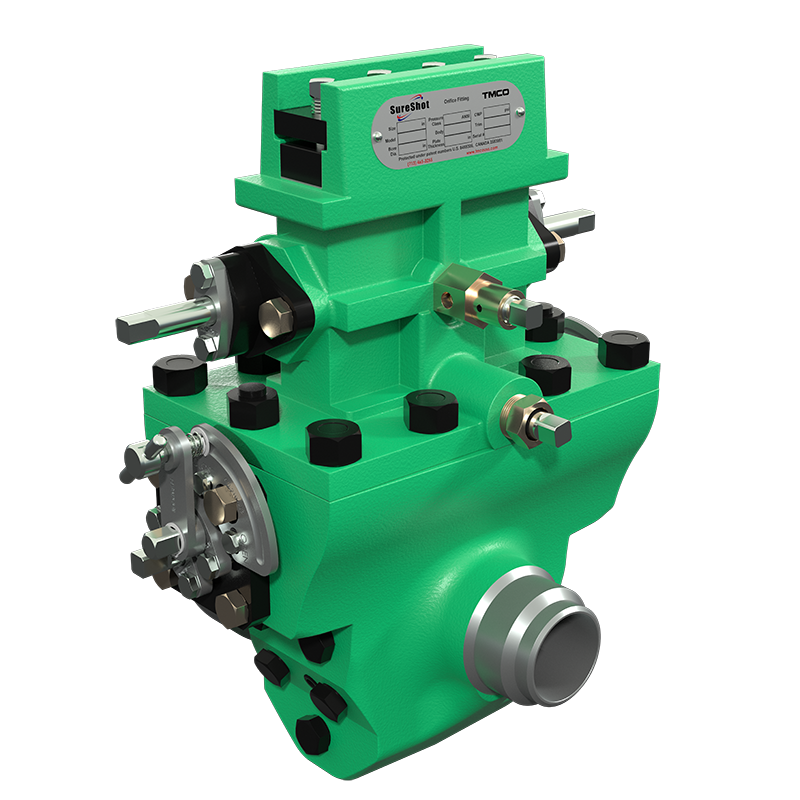

TMCo Sureshot

TMCo Inc. is an Oklahoma corporation specializing in the manufacture of orifice fittings for the measurement of natural gas. The company was founded in September 2003 and has manufacturing facilities in Wewoka, Oklahoma; fabrication facilities in Simonton, Texas; and sales and administrative offices in Houston, Texas. TMCo has a world wide network of sales representatives. TMCo is ISO 2001 certified and our products are CRN approved and conform to all applicable industry standards.

TMCo's current product line consists of the SURE SHOT® Dual Chamber orifice fitting in 2”, 3”, 4”, 6”, 8”, 10”, 12”, 16” sizes and SURE SHOT® Single Chamber orifice fitting in 2”, 3”, 4” and 6” sizes and are available in 150, 300 and 600 ANSI ratings. Compared to other orifice fittings on the market, the “Sure-Shot” is simpler, safer and more economical to operate. The SURE SHOT® orifice fitting design meets or exceeds the guideline specifications, under the AGA3/API 14.3 & ISO 5167 standards for manufacturing custody transfer differential products for both the domestic and international market. In addition, we fabricate meter tubes consisting of an orifice fitting, upstream and downstream pipe sections, and flow conditioners.

TMCo's facility in Wewoka, Oklahoma, has grown from 20,000± sq ft to 51,000± sq. ft, and houses all necessary machinery and equipment to support manufacturing of our orifice fitting products. Additionally, a 7,000 sq ft warehouse space is utilized for storage of raw materials. With TMCo's skilled work force in Oklahoma they manage all product assembly, testing and quality control functions, as well as warehousing and inventory control.

TMCo Inc. has over 60,000 Sure Shot Dual and Single Chamber Orifice Fittings installed worldwide!

Single Chamber Fittings

Single Chamber Fittings are the most widely accepted means for flow measurement of gas and other hydrocarbons in the oil, gas & petrochemical industry.

Sure Shot® single chamber fitting provides both cost and time saving opportunities to the operator.

Single Chamber Features:

Single Chamber Fitting Applications:

- Gas Gathering

- Compressor Stations

- Onshore – Offshore Production

- Coal-Seam Gas Measurement

- Gas Distribution

- Gas Transmission

- Process Gas Plant

Fitting Pressure Ratings:

- ANSI Class 150 (285 PSI CWP)

- ANSI Class 300 (740 PSI CWP)

- ANSI Class 600 (1480 PSI CWP)

Standard Materials of Construction:

- Body Material – A-216 WCB/WCC - Consult factory for any other fitting body material

- Flange Ratings – ANSI Class 150 to ANSI Class 600

- Fitting End Connections – F x W

- Raised Face Flange is standard for ANSI Class 150 to ANSI Class 600

Conforms to the following industry standards:

- AGA 3/API 14.3, ISO-5167

- ANSI B31.3, MSS SP-55, ANSI B16.5

- Fittings conform to NACE MR-01-75-2000

Operating Range:

- Sizes 2” thru 6” ANSI Class 150, 300, & 600

- Temperature -20° F to 275° F (-29° C. to 135° C.)

Quality Check:

- Hydrostatic test 1-1/2 times rated CWP.

- Tested for positive plate seal, pressure tap integrity, seal protrusion and eccentricity

Request More Information

Dual Chamber Orifice Fitting

Sure Shot® Dual Chamber Orifice fittings fully conform to the latest AGA 3/API 14.3 stringent requirements. They require no added uncertainty and provide accurate performance over the orifice plate beta ratio range from 0.1 to 0.75 within 0.5% flow accuracy to theoretical value.

Dual Chamber Features:

- Two-piece body allows fast, safe inexpensive orifice plate change under pressure

- Protected positive orifice plate seal design extends service life

- Meets or exceeds all industry specifications (AGA3/API 14.3)

- 2”-16” ANSI Classes 150-600. For higher ratings consult factory

- Few moving parts, positive sealing with low maintenance

- Unique safety lock helps to prevent accidental opening under pressure while removing the orifice plate, indicates proper carrier location, and provides precise plug operation positioning

Fitting Pressure Ratings:

- ANSI Class 150 (285 PSI CWP)

- ANSI Class 300 (740 PSI CWP)

- ANSI Class 600 (1480 PSI CWP)

Standard Materials of Construction:

- Body Material – A-216 WCB / WCC

- Flange Ratings – ANSI Class 150 to ANSI Class 600 inclusive.

- Fitting End Connections – F x W, F x F ?Note: RTJ Flange facing available upon request. Consult factory for any other fitting body material.

Conforms to the following industry standards:

- AGA 3/API 14.3, ISO-5167

- ANSI B31.3, MSS SP-55, ANSI B16.5

- Fittings available for NACE MR-01-75-2000

- CRN Certified

Operating Range:

- Sizes 2” thru 16” ANSI Class 150, 300, & 600

- Temperature -20° F to 275° F (-29° C. to 135° C.)

- Schedule 40 and schedule 80 standard. Note: Consult factory for larger sizes and other operating conditions.

Quality Check:

- Hydrostatic test 1-1/2 times rated CWP.

- Tested for positive plate seal, pressure tap integrity, seal protrusion and eccentricity

Specifications:

Please download the Product Brochure PDF for more information.

Request More Information

Box 187

Box 187

1018 Prescott Dr Unit #2

1018 Prescott Dr Unit #2