When leading industries across the world need solutions to their safety pressure relief and isolation problems, they turn toward us. So, what sets us apart from the rest? Rupture Pin Technology, a brand of Taylor Valve Technology, manufactures the most accurate, reliable valves available. Our patented pin technology ensures that your process and people are safe even during the most challenging and hazardous operations.

Each of our customers reports better performance, greater accuracy, and significantly reduced downtime year-over-year. Whether you need a safety pressure relief valve, an emergency shut off valve or a custom valve for your application we can help. Consult with a representative for a custom-tailored solution today.

Model C - ASME

DESCRIPTION

The Model C-ASME is the ASME certified version of our angle body Model C relief valve. The Model C-ASME is UD stamped. It holds a bubble-tight, closed position until pressure reaches an exact set point. At set point, the valve instantly opens to relieve pressure from a protected system. The valve features a wide variety of pressures ratings and settings.

SPECIFICATIONS

Set Pressure: 15 – 1,480 PSI

Accuracy: + / – 5% above 40 PSI, ±2 PSI Below 40 PSI

Connections: Flange connections available.

Seals: Available for high & low temperatures, Viton standard.

Standard Materials: ASME Section II materials.

The C-ASME now offers same inlet and outlet connections with the option of having the outlet being one size larger than the inlet.

Download brochure for complete details on features, advantages and benefits of the Model C-ASME valve.

NOTE: Taylor Valve reserves the right to change product designs and specifications without notice.

APPLICAITONS

The Model C-ASME relief valve is designed specifically to be installed on ASME Section VIII UD coded vessels. It provides safety for a variety of pressure relief applications including but not limited to: Oil and Gas Production, Pipeline, Well Drilling, Chemical Processing, Food Processing, Waste Water Processing, Pharmaceutical Processing, Pulp and Paper Plants, and anywhere that conventional relief valves and rupture discs are used.

Get More Information

Model CB

DESCRIPTION

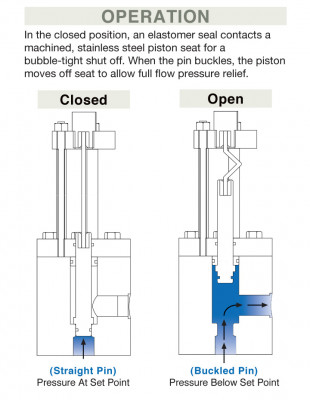

The Model CB holds a bubble-tight, closed position until pressure reaches an exact set point. At set point, the valve instantly opens to relieve pressure from a protected system.

SPECIFICATIONS

Set Pressure: 10 – 2,000 Psi

Accuracy: + / – 5%

Connections: Custom and standard available.

Seals: Available for high & low temperatures, Viton standard.

Standard Materials: Complete stainless-steel body, piston, and trim. Other exotic alloy materials optional.

Download brochure for complete details on features, advantages and benefits of the Model CB valve.

NOTE: Taylor Valve reserves the right to change product designs and specifications without notice.

APPLICATIONS

The Model CB valve provides safety for a variety of pressure relief applications including but not limited to: Oil and Gas Production, Pipeline, Well Drilling, Chemical Processing, Food Processing, Waste Water Processing, Pharmaceutical Processing, Pulp and Paper Plants, and anywhere that conventional relief valves and rupture discs are used.

Model D

DESCRIPTION

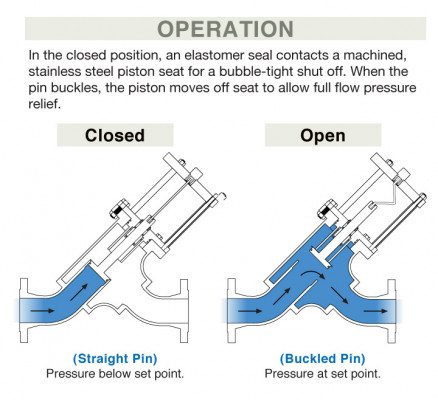

The Model D is an inline body safety pressure relief valve that holds a bubble-tight, closed position until pressure reaches an exact set point. At set point, the valve instantly opens to relieve pressure from a protected system.

SPECIFICATIONS

Set Pressure: 5 – 2,000 Psi

Accuracy: + / – 5%

Connections: Custom and standard available.

Seals: Available for high & low temperatures, Viton standard.

Standard Materials: Carbon steel body with stainless-steel trim, other materials optional.

Download brochure for complete details on features, advantages and benefits of the Model D valve.

NOTE: Taylor Valve reserves the right to change product designs and specifications without notice.

APPLICATIONS

The Model D valve provides safety for a variety of pressure relief applications including but not limited to: Oil and Gas Production, Pipeline, Well Drilling, Chemical Processing, Food Processing, Waste Water Processing, Pharmaceutical Processing, Pulp and Paper Plants, and anywhere that conventional relief valves and rupture discs are used.

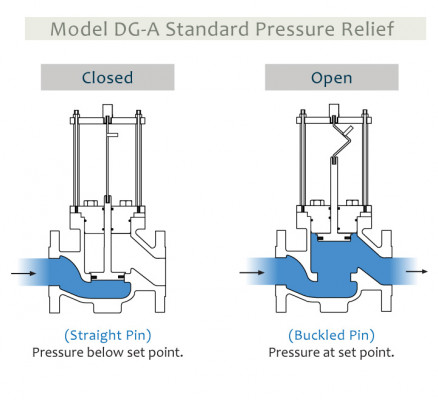

Model DG

DESCRIPTION

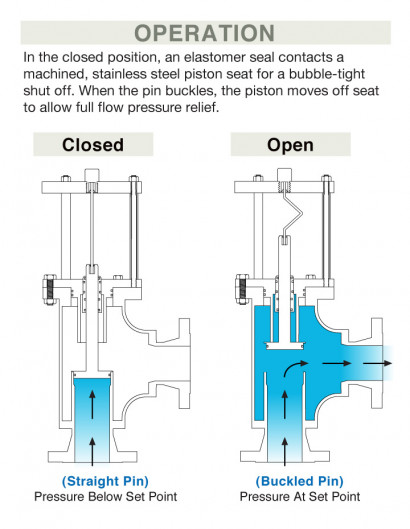

The Model DG is an inline valve that holds a bubble-tight, closed position until pressure reaches an exact set point. At set point, the pin buckles and the valve instantly opens to relieve pressure from a protected system.

SPECIFICATIONS

Set Pressure: 5 – 2,000 Psi

Accuracy: + / – 5%

Connections: Standard and custom available.

Seals: Available for high & low temperatures, Viton standard.

Standard Materials: Stainless-steel body with stainless-steel trim is standard, other exotic materials optional.

Download brochure for complete details on features, advantages and benefits of the Model DG valve.

NOTE: Taylor Valve reserves the right to change product designs and specifications without notice.

APPLICATIONS

Box 187

Box 187

1018 Prescott Dr Unit #2

1018 Prescott Dr Unit #2 NEW

NEW