Focus® 2.0 Optical Gas Flow Meter FAQS

Why choose the Focus® 2.0 Optical Gas Flow Meter?

Why choose the Focus® 2.0 Optical Gas Flow Meter?

-

High measurement accuracy (up to ±2.5%)

-

High turn-down ratio (1500:1)

-

Wide pipe diameter range (4” to 36”)

-

Easy installation and maintenance

-

Accuracy not affected by gas composition

-

Minimal flow blockage and low-pressure drop

-

Compliance with ERCB, OGC, AGA regulations and directives

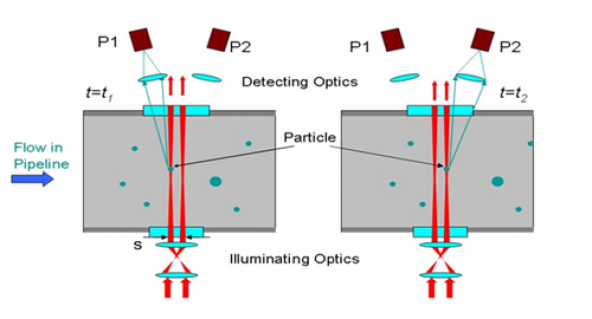

What is Laser-2-Focus (L2F) Velocimetry?

What is Laser-2-Focus (L2F) Velocimetry?

L2F Velocimetry is the key operating principle of the Focus 2.0 OFM. Gas particles flow through the pipe, pass through sheets, laser light scatters and is detected by 2 photodetectors. Time between signals are measured and the velocity of particles are calculated.

What area classification is the Focus 2.0 approved for?

The Optical Flow Processor is approved for Class 1 Zone 1. The Focus® 2.0 Probe is approved for

Class 1.

What are the advantages of the Focus 2.0 OFM versus Ultrasonic Flow Meters?

-

Turn- down ratio

-

Operating temperature

-

Resistance to pipe vibration

-

Better performance in variable flow conditions

What are the advantages of the Focus 2.0 OFM versus thermal mass flow meters?

-

Immunity to gas composition

-

Higher resistance to probe contamination

-

Immediate feedback to interruptions in flow readings

What maintenance is required for the Focus® 2.0?

Simple cleaning of the probe windows is quick and easy typically completed within 30 minutes.

How often is calibration required for the Focus 2.0?

No further system calibration is required after installation and commissioning.

What is the long-term reliability of the Focus 2.0?

The system’s laser is rated for an operational lifetime of 5 years (easily replaced).

Box 187

Box 187

1018 Prescott Dr Unit #2

1018 Prescott Dr Unit #2 NEW

NEW