Providing Solutions: Water Alternating Gas Injection Project

A longstanding client in Southeast Saskatchewan approached us with a challenge they were having in their water alternating gas (WAG) injection project.

A longstanding client in Southeast Saskatchewan approached us with a challenge they were having in their water alternating gas (WAG) injection project.

Our team was familiar with this WAG injection project as we supplied carbon steel choke valves for their CO2 injection and stainless-steel choke valves for their water injection.

The Challenge

Our client was looking for a solution to improve their process for the isolation of their CO2 and water injection lines.

Our Solution

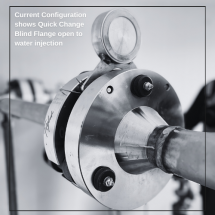

Kings Energy Services in-house manufactured Quick Change Blind Flanges. Our Quick-Change Blind Flanges proved to be a game-changer for our client's injection processes. Not only did it significantly improve the isolation of CO2 and water injection lines, but it also streamlined the process of switching between injection methods. What used to take considerable time and manpower can now be accomplished in under 5 minutes with the expertise of just one maintenance personnel.

Advantages of Quick Change Blind Valves

Quick and Easy Isolation and Flow Direction Change

Quick and Easy Isolation and Flow Direction Change

The primary advantage of Quick Change Blind Flanges lies in their ability to facilitate swift isolation or direction change of fluid flow. This feature provides our clients with operational agility, enabling them to respond promptly to changing conditions and process requirements.

Safe Operation with Alignment Pins

Safe Operation with Alignment Pins

Safety is paramount in the oil and gas industry, and our Quick Change Blind Flanges address this concern. Equipped with alignment pins, they ensure a secure and precise installation, minimizing the risk of accidents or leaks during the process.

Simple Operation and Customizable Applications

Simple Operation and Customizable Applications

Designed with user-friendliness in mind, our Quick Change Blind Flanges offer straightforward operation, eliminating the need for complex procedures. Furthermore, they are highly customizable, making them suitable for a wide range of applications in various industries, including oil and gas, processing, slurry, marine, and more.

CRN Certified

CRN Certified

We understand the significance of reliability in critical operations. Our Quick Change Blind Flanges are CRN certified, ensuring that they meet the highest industry standards and provide a trustworthy solution for our client's injection needs.

Available in Flange and Butt Weld

Available in Flange and Butt Weld

To accommodate diverse installation preferences, we offer Quick Change Blinds in both flange and butt weld configurations, providing flexibility to match our client's specific requirements.

Stainless Steel and Carbon Steel Options

Stainless Steel and Carbon Steel Options

Recognizing the importance of material selection, our Quick Change Blind Flanges are available in both stainless steel and carbon steel variants, catering to different environments and media.

Grease Zerk for Proper Lubrication and Corrosion Minimization

Grease Zerk for Proper Lubrication and Corrosion Minimization

Maintenance and longevity are crucial considerations in any equipment. With the incorporation of Grease Zerk on studs, our Quick Change Blind Flanges ensure proper lubrication and minimize the risk of corrosion, thus extending their service life.

Applications for Quick Change Blind

Oil and Gas - Production and Refining, Pipeline, CO2/Well Injection, Water Injection

Oil and Gas - Production and Refining, Pipeline, CO2/Well Injection, Water Injection

Processing applications - Chemical, Synthetic, Rubber, Food and Beverage, Pulp and Paper

Slurry applications - Cement Plants, Mining

Marine applications - Aboard ships and tankers, Terminals and storage

Plant Turnaround and Maintenance

Through collaboration with our client Kings Energy Services was able to provide a solution that not only solved their challenge but helped streamline their WAG injection project when switching between medias. By improving isolation processes, enhancing operational speed, and prioritizing safety, we have empowered our client to excel in their operations.

Box 187

Box 187

1018 Prescott Dr Unit #2

1018 Prescott Dr Unit #2 NEW

NEW