Safety relief valves are mechanical devices designed to protect equipment or systems from overpressure. They work by opening to release excess pressure when it exceeds a predetermined limit, thereby preventing damage to the system or equipment. At Kings Energy Services we are the proud distributor of many different Safety Relief Valves that include

Taylor Valve Technologies

Taylor Valve Technologies

Kingston Valves

There are many different types of safety relief valves, including spring-loaded, pilot-operated, and bellows-type. The selection of the appropriate valve depends on the specific application and the level of pressure required. Proper maintenance and testing of safety relief valves are essential to ensure their reliability and effectiveness in protecting the system or equipment.

8250 Relief Valve

DESCRIPTION

8250 THREADED & FLANGED VALVES

The Taylor 8250 Safety Relief Valve is manufactured in accordance with the requirements of ASME Boiler and Pressure Vessel Code, Section VIII, Division 1 for Air/Gas and Liquid service making it an excellent choice for Air, Gas or Liquid relief applications

The 8250 redesign is just the beginning of new things to come from Taylor Valve, the ORIGINAL SELF ALIGNING TECHNOLOGY company. Self-Aligning seat technology allows for repeatable uses without resetting or repair.

FEATURES

- Designed with self-aligning seat technology

- C orifice with pressure to 10,000 psi

- L orifice in 3 x 4 and 4 x 6 flanged connections

- M orifice in a 4 x 6 flanged connection

- Increased capacity in all orifices

- Top entry style valve H orifice and larger

- API connections available in most flanged connections

- All orifices are ASME certified by the National Board of Boiler and Pressure Vessels in accordance with Sec VIII Div I. for air/gas and liquid service.

SPECIFICATIONS

Please download the 8250 Product Brochure PDF for more information.

APPLICATIONS

- Compressors

- Separators

- Heater Treaters

- Free Water Knockouts

- Scrubbers

- Dehydrators

- Thermal Relief

- Gas Production Units,

- Transmission and Gathering Lines

- Chemical Plants

- Refineries

- Meter Runs

- Gas Plants

- Other Industrial Applications

Get More Information

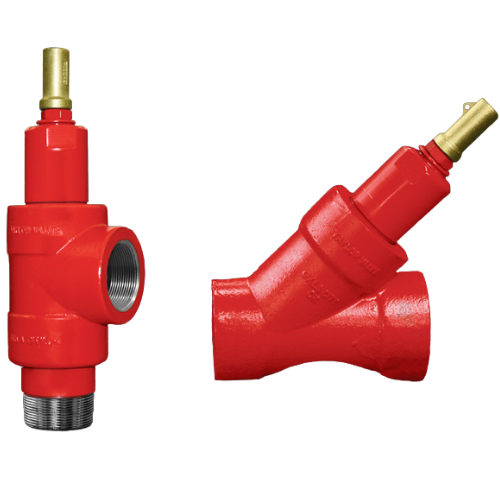

19BV Series Pressure Relief Valve

DESCRIPTION

19BV Series Pressure Relief Valve

The Taylor 19BV Series Pressure Relief Valve is manufactured in accordance with the requirements of ASME certified by the National Board of Boiler and Pressure Vessels in

accordance to Sec VIII Div I making it an excellent choice for Air, Gas or Liquid relief applications

FEATURES

- Soft seat for reliable, leak free performance to 90% of set pressure

- Easy repair and maintenance

- Balanced disc/cage assembly designed with a single o-ring balancing seal to operate in high back pressure conditions.

- Optimized design allows the valve to operate without chatter or intricate seals.

- ASME certified by the National Board of Boiler and Pressure Vessels in accordance to Sec VIII Div I for air/gas and liquid service.

- NPT threaded and flanged connections

SPECIFICATIONS

Please download the 1900BV Product Brochure PDF for more information.

APPLICATIONS

The Taylor 19BV Pressure Relief Valve has numerous application uses. Since the Series 19BV is certified for both gas and liquid on both orifices, it can be installed

where relief applications that have variable back pressure are present. Thermal valves, pump recycle, separators (liquid side), water knockouts, etc. are just a few examples of

application uses.

Get More Information

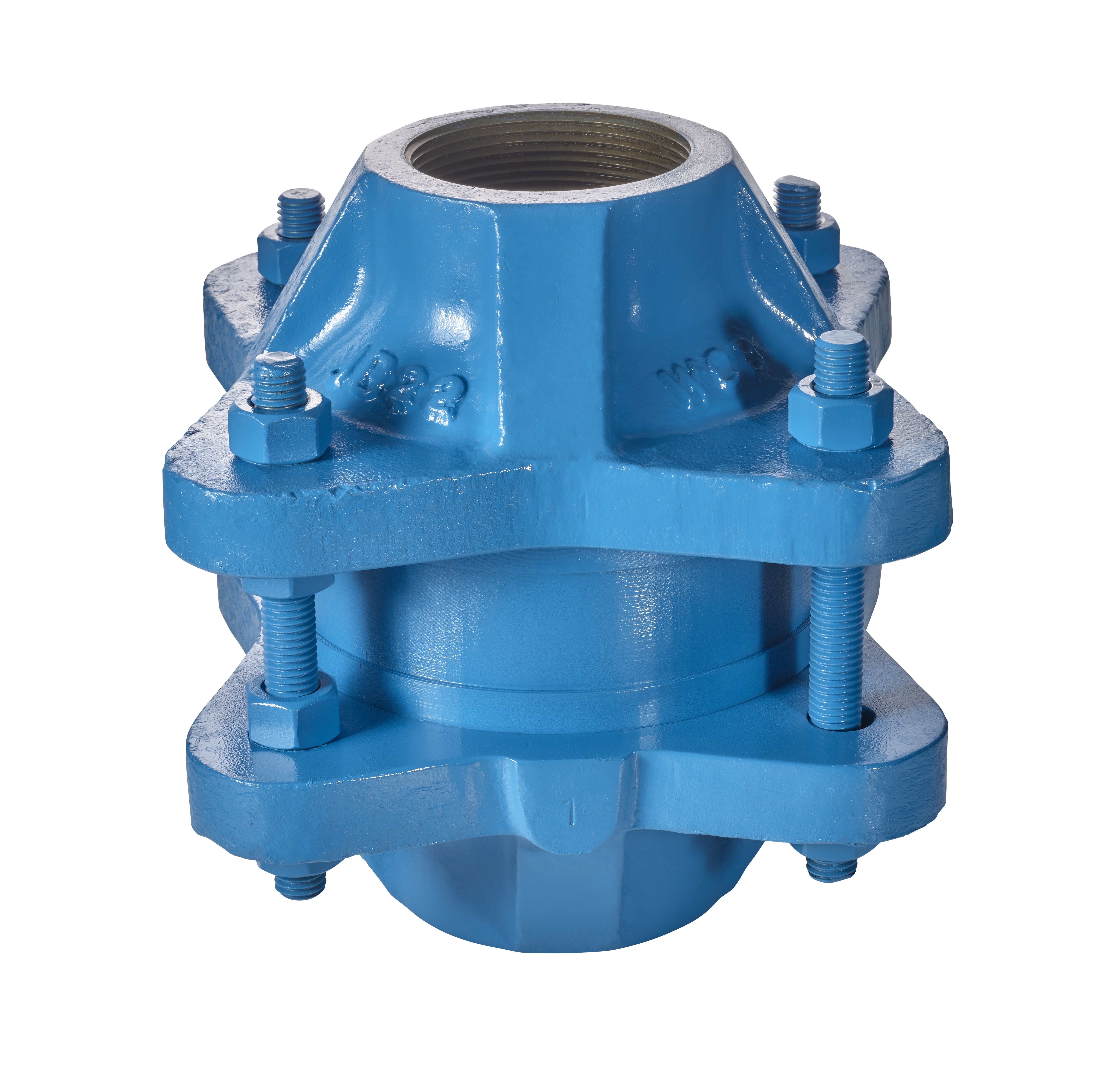

8200/8300 Series Safety Relief Valve

Our 8200/8300 Series safety relief valves are engineered and manufactured to the highest standards and feature a high endurance soft seat which guarantees a bubble-tight seal for hundreds of “pops”. Our unique patented radius disc design guarantees dependable, repeatable relief even under the most difficult of conditions.

Available in flanged or threaded configurations.

Taylor Valve Technologies 8200 Series are no longer being produced Kings Energy Services can support 8200 series valves that are in service. If you require a replacement for your 8200 Series please to Taylor Valve Technologies new 8250 Series.

Download the brochure for more information and complete valve specifications.

Applications

Air, gas, or liquid relief applications, compressors, separators, heater treaters, free water knockouts, scrubbers, dehydrators, thermal relief, gas production units chemical plants, refineries, gas, plants and other industrial applications.

Get More Information

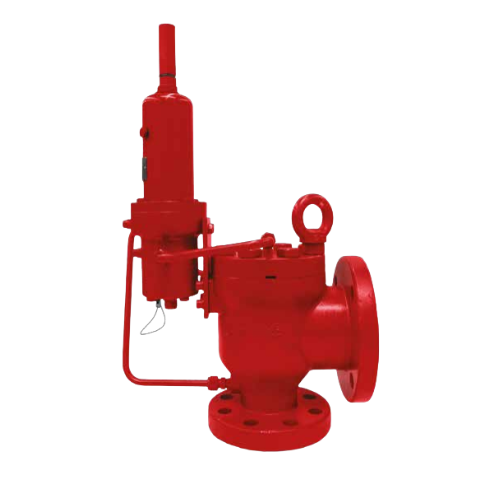

9300 Modulator Pilot Valve

The Series 9300 Modulator Pilot Valve / Modulating Safety Valve with the non-flowing pilot provides highly reliable system overpressure protection.

Features & Benefits

- Easily Adjusted

The adjustable set pressure is accurate and dependable. Adjustable blowdown is external, which reduces time and cost consuming expenditures of valve removal. System downtime is also greatly reduced. - Maintenance Cost Is Cut

With a replaceable soft seat, expensive parts and time-consuming lapping of metal seats are no longer necessary. - ASME Section VIII Code Stamp

Used for air, gas, and vapor service, the capacity is assured by an independent third party, the ASME National Board Laboratory in Columbus, Ohio. - Increased Output of System

The valve can be set within 5% of system operating pressure allowing the process to be maintained at close tolerance without valve leakage. This results in greater process system output. - Dirty Service

The pilot is a non-flowing design minimizing the entry of dirt and the accumulation of hydrates. Most of the contaminates will be removed in the coalescing filter upstream of the pilot. The internal cartridge type filter is standard on all Taylor Pilots and finishes the gas before it enters the pilot cavity. Inline tubing external filter is also available. - Pilot is Mounted Vertically

Consistent set pressure and blowdown are assured compared to horizontally mounted pilots that are erratic.- Orifice Nozzles. The orifice size may be changed by replacing a single component. There are multiple orifice sizes for each nominal body size.

- Built-in Field Test Port. Provides the ability to accurately verify the set pressure with the valve in place and in service.

- Durable, Rugged Mounting of Pilot. Extra rigid mounting against the body protects the pilot from system vibration.

Applications

This valve can be used for air, gas, vapor, and most mixed-phase services.

Get More Information

7700 Series Back Pressure Regulator

The 7700 Back Pressure Regulator (BPR) Series is an excellent and economical device for relief and control of pressure in liquid and gas service. Valve control is accomplished by upstream pressure acting on a lapped piston, which is acted on by a spring. The valve will open at a determined set pressure, which is field adjustable.

Applications

Pump Bypass, Pump Relief, Well Hookups and Closed Loop Systems, Balanced Valve Applications, By- Pass to Casing, Pump Backpressure - Allows the pump to operate more efficiently, Pipeline Thermal Relief

8400 Series Vapor Valve

The 8400 Series Vapor Valve provides pressure relief in applications where hazardous vapors are to be piped away. The Vapor Valve is a non-ASME code valve, and specifically addresses low-pressure applications (below 15 PSIG). The valve uses a spring which directly opposes system pressure. A fully-guided, stainless steel disc senses the system pressure. If the system pressure ever reaches the valve’s determined set pressure, the disc will release from its seated position, venting system pressure.

Applications

Glycol Reboiler Safety Relief, BTEX Safety Relief, Vessel Safety Relief below 15 PSI and Tank Blanketing.

Request for information

EPC Environmental Protection Cap

DESCRIPTION

The EPC ensures valve and system protection from environmental elements, enhancing service life and limiting repair costs. Our unique lanyard design and NOW our new threaded option add a leak detection capability that sets us apart from other competitive products.

LANYARD SPECS

Connection Size: 1/2″ – 4″

Connection Type: Lanyard Strap

Body Material: Vinyl and highly engineered plastic compound

Max. Working Pressure: 3,000 psi

The design also incorporates a whistle device that signals when a low-pressure leak is occurring.

NOTE: Taylor Valve reserves the right to change product designs and specifications without notice.

THREADED SPECS

Connection Size: 1″- 2″

Connection Type: Threaded

Body Material: Nylon 6-6

Max. Working Pressure: 3,000 psi

NOTE: Taylor Valve reserves the right to change product designs and specifications without notice.

APPLICATIONS

Valve and System Protection, Leak Detection.

Applications

Valve and System Protection, Leak Detection.

Get More Information

Inline Vent Valve - L10L

The L10L design was created to exceed industry needs. Extensive research and development has produced a product that achieve both superior sealing performance and industry leading flow rates.

Available Sizes: 2” (50mm), 3” (75mm) and 4” (100mm)

Pressure Settings: 1 to 16 osig (in 1.0 osig Increments)

Vacuum Settings: 0.4 osig (for pressure/vacuum configuration), None (for pressure only configuration)

Valve Configuration: Pressure / Vacuum, Pressure Only

Casting: Aluminum

Diaphragm Materials: Black Buna-N, Blue FKM

Flange Gasket: Black Buna-N, Blue FKM

Weight: Zinc-Plated Steel or Stainless Steel

Optional: Polyester/PTFE Coating

End of Line Stack Vent Valve L10E

The L10E design was created to exceed industry needs. Extensive research and development has produced a product that achieve both superior sealing performance and industry leading flow rates.

Available Sizes: 2” (50mm), 3” (75mm) and 4” (100mm)

Pressure Settings: 1 to 16 osig (in 1.0 osig Increments)

Vacuum Settings: 0.4 osig (for pressure/vacuum configuration), None (for pressure only configuration)

Valve Configuration: Pressure / Vacuum, Pressure Only

Casting: Aluminum

Diaphragm Materials: Black Buna-N, Blue FKM

Flange Gasket: Black Buna-N, Blue FKM

Weight: Zinc-Plated Steel or Stainless Steel

Optional: Polyester/PTFE Coating

Weight Loaded Pressure Relief Valve L11E

LaMot Valve & Arrestor Model L11E weight loaded pressure relief valve is designed to be used in applications where additional relief is necessary. It can be used in conjunction for emergency relief but that is not why it was designed. Pressure relief valves provide relief from excessive internal pressure which may cause tank damage. Calibrated weights are available for various setting.

Size: 2” (50mm) through 10″ (250mm)

Casting Material: Aluminum (non-sparking), Carbon Steel, Stainless Steel

Pallet Material: Polyphenylene Sulfide (PPS)

Diaphragm Materials: Buna-N, Blue FKM or FEP

Calibrated Weight Material: Zinc-Plated Steel (for Aluminum and Carbon Steel

valves), Stainless Steel (for Stainless Steel valves)

Bolting Class: 150# ASME

Pressure Settings: 0.5 osig to 24 osig (0.5 osig increments)

Leak Rate is compliant with API 2000

Pressure/Vacuum Relief Valve L12E

The LaMOT Valve & Arrestor Model L12E PVRV design was created to exceed industry needs. Extensive research and development have produced a product that achieve both superior sealing performance and industry leading flow rates, while also allowing customers to reach required flow with a potentially smaller sized valve. The pressure vacuum relief valve is designed to protect your tank from damage created by overpressure or excessive vacuum. Costly product evaporation losses due to normal tank “breathing” are greatly reduced. The Model L12E superior sealing valves are developed to minimize fugitive emissions while providing increased protection and safety to tank equipment and on-site personnel.

Size: 2” (50mm) through 10” (250mm)

Body Material: Aluminum, Carbon Steel, Stainless Steel

Pallet Material: PPS (Polyphenylene Sulfide)

Diaphragm Materials: Buna-N, Blue FKM or FEP

Calibrated Weight Material: Zinc-Plated Steel (for Aluminum and Carbon Steel valves), Stainless Steel (for Stainless Steel valves)

Bolting Class: 150# ASME

Available Pressure Settings: 0.5 osig to 24 osig (in 0.5 osig Increments)

Available Vacuum Settings: 0.4 osig, 0.5 osig to 24 osig (in 0.5 osig increments)

Leak Rate is compliant with API 2000

Vent to Atmosphere, Pressures up to 24 osig

Threaded In-Line Flame Arrestor L76T-UF

The L76T-UF model is designed to inhibit flame propagation in gas piping systems and to protect low pressure tanks containing flammable liquids. Arrestors protect low flash point liquids from external sources of ignition. This provides increased fire protection and safety.

Connection Sizes: 2”, 3” and 4” NPT

Housing standard material: carbon steel, 316SS

Bases standard material: carbon steel

Flame element standard material: stainless steel

Operational Temperature Range: -4 to 140 oF (-20 to 60 oC)

Gas Group: NEC D; IEC IIA (MESG > 0.90 mm)

Maximum Operational Pressure: (see charts and IOM)

Burn Time: tBT 2.5 minutes or better at Atmospheric Pressure (see charts and IOM) • Bi-directional with respect to flow and ignition source

Round Pan Thief Hatch LH12-TH

The LaMOT Valve & Arrestor Model L12-TH Thief Hatch incorporates a spring loaded pressure/vacuum relief valve within the device. Thief Hatches are used on steel or fiberglass (FRP) low pressure storage tanks. The hatch has a gauging hook integrated to the base to be used while sampling the tank, providing access for level gauging, sampling, and overpressure/vacuum protection for the tanks, all in one compact design. Superior sealing is achieved from an active envelope pressure gasket that expands around the base to increase seal until the designated pressure setting is reached. This design saves you money by greatly reducing vapor loss compared to a traditional thief hatch design.

Size: 8”

Bolting: API 12

Available Pressure Settings: 4, 6, 8, 10, 12, 16, 24, & 32 osig

Available Vacuum Settings: 0.4. 0.9 & 3.5 osig

Leak Rate: Less than 1 SCFH of Air @ 90% of Set Pressure

Casting: Aluminum (non-sparking)

Envelope Gasket: HNBR, FKM or Fluorosilicone

Vacuum Diaphragm: HNBR, FKM, Fluorosilicone or Fluoropolymer

Springs: Galvanized Steel or Inconel® X-750

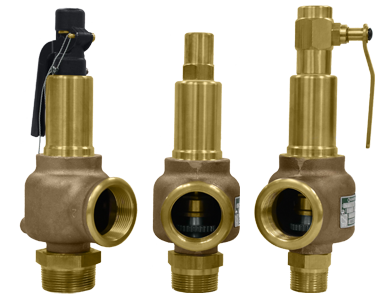

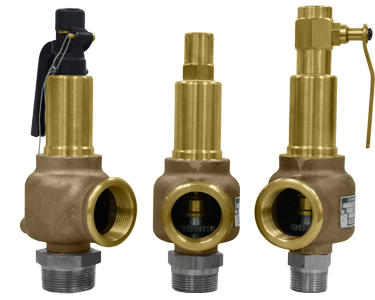

KNG 563

Kingston Side Outlet Relief Valve

– ASME Section I and Section VIII

– NB Certified for Liquid, Air/Gas, and Steam

Sizes: 1/2″ to 2-1/2″

Pressure Range: 5 – 300 (Air/Gas); 5 – 300 (Steam)

Applications

Steam Boilers, Air compressors, Dryers, Receivers, Pressure Vessels, Piping Systems, Accumulators, Reducing Stations, Tanks, Inter/After Coolers, Cooking Equipment, Autoclaves, Sterilizers, or whatever higher capacity pressure protection or relief may be required.

KNG 570

Kingston Side Outlet Relief Valve

– ASME Section VIII

– NB Certified for Liquid, Air/Gas, and Steam

Sizes: 1/2″ to 2-1/2″

Pressure Range: 5 – 300 PSI (Air/Gas); 5 – 250 PSI (Steam)

Applications

Steam Boilers, Air compressors, Dryers, Receivers, Pressure Vessels, Piping Systems, Accumulators, Reducing Stations, Tanks, Inter/After Coolers, Cooking Equipment, Autoclaves, Sterilizers, or whatever higher capacity pressure protection or relief may be required.

Get More Information

KNG 560

Kingston Side Outlet Relief Valve – ASME Section I and Section VIII

– NB Certified for Liquid,

Air/Gas, and Steam

Sizes 1/2″ to 2-1/2″

Pressure Range 5 – 300 PSI (Air/Gas); 5 – 250 PSI (Steam)

Applications

Steam Boilers, Air compressors, Dryers, Receivers, Pressure Vessels, Piping Systems, Accumulators, Reducing Stations, Tanks, Inter/After Coolers, Cooking Equipment, Autoclaves, Sterilizers, or whatever higher capacity pressure protection or relief may be required.

Get More Information

KNG 573

Kingston Side Outlet Relief Valve

– ASME Section VIII

– NB Certified for Liquid, Air/Gas, and Steam

Sizes: 1/2″ to 2-1/2″

Pressure Range: 5 – 300PSI (Air/Gas); 5 – 250 PSI(Steam)

Applications

Steam Boilers, Air compressors, Dryers, Receivers, Pressure Vessels, Piping Systems, Accumulators, Reducing Stations, Tanks, Inter/After Coolers, Cooking Equipment, Autoclaves, Sterilizers, or whatever higher capacity pressure protection or relief may be required.

KNG 740

Kingston KNG740 Side Outlet Relief Valve

– ASME Section VIII

– NB Certified for Liquid, Air/Gas, and Steam

Sizes: 1/2″ to 3″

Pressure Range: 5 – 1500 PSI (Liquid and Air) ; 5 – 300 PSI (Steam)

Applications

Pressure Vessels, Pumps, Hydraulics, Tanks, Steam Systems, Chemical, Cryogenic, Air and Gas Compressors, Separators, By-pass and Over Pressure Protection. Choose for most industrial applications requiring a safety relief valve.

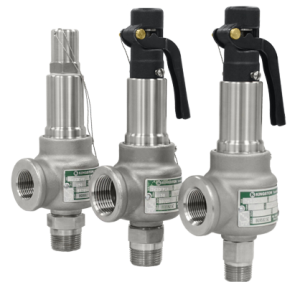

KNG 741

Kingston KNG 741 Side Outlet Relief Valve

– ASME Section VIII

– NB Certified for Liquid, Air/Gas, and Steam

Sizes: 1/2″ to 3″

Pressure Range: 5 – 1500 PSI (Liquid & Air); 5 – 300 PSI (Steam)

Applications

Pressure Vessels, Pumps, Hydraulics, Tanks, Steam Systems, Chemical, Cryogenic, Air and Gas Compressors, Separators, By-pass and Over Pressure Protection. Choose for most industrial applications requiring a safety relief valve.

KNG 742

Kingston KNG 742 Side Outlet Relief Valve

– ASME Section VIII

– NB Certified for Liquid, Air/Gas, and Steam

Sizes: 1/2″ to 3″

Pressure Range: 5 – 1500 PSI (Liquid & Air); 5 – 300 PSI (Steam)

Applications

Pressure Vessels, Pumps, Hydraulics, Tanks, Steam Systems, Chemical, Cryogenic, Air and Gas Compressors, Separators, By-pass and Over Pressure Protection. Choose for most industrial applications requiring a safety relief valve.

KNG 743

Kingston KNG 743 Side Outlet Relief Valve

– ASME Section VIII

– NB Certified for Liquid, Air/Gas, and Steam

Sizes: 1/2″ to 3″

Pressure Range: 5 – 1500 PSI (Liquid & Air); 5 – 300 PSI (Steam)

Applications

Pressure Vessels, Pumps, Hydraulics, Tanks, Steam Systems, Chemical, Cryogenic, Air and Gas Compressors, Separators, By-pass and Over Pressure Protection. Choose for most industrial applications requiring a safety relief valve.

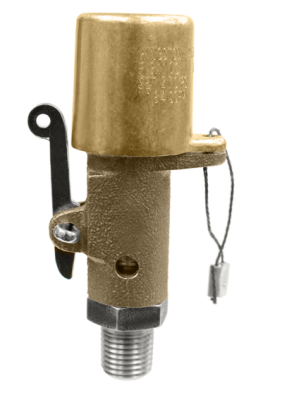

MODEL 110C

Kingston ASME Code High Pressure Safety Valve

Sizes: 1/4″,3/8″

Pressure Range: 25 – 600

Applications

Compressed Air Systems

MODEL 112CR

Kingston ASME Code Stainless Steel Safety Valve

Sizes: 1/4″,3/8″,1/2″

Pressure Range: 25 – 300

Applications

Compressed Air Systems, Stainless Steel, Steam Applications

MODEL 112CSS

Kingston ASME Code Safety Valve

Sizes: 1/4″,3/8″,1/2″

Pressure Range: 25 – 300

Applications

Compressed Air Systems, Steam Applications

MODEL 112CSSEN

Kingston ASME Code Nickel Plated Safety Valve

Sizes: 1/4″,3/8″,1/2″

Pressure Range: 25 – 300

Applications

Compressed Air Systems, Steam Applications

MODEL 118CSS

Kingston ASME Code High Capacity Safety Valve

Sizes: 1/4″,3/8″,1/2″,3/4″,1″

Pressure Range: 25 – 300

Applications

Compressed Air Systems

Box 187

Box 187

1018 Prescott Dr Unit #2

1018 Prescott Dr Unit #2